View: Time: 2017-11-24 19:21:38

Glass of a magical material, it is born for the light! Color, the result of the role of light and objects! Opaque objects have only a reflective color, and glass, in addition to being able to reflect colors, can transmit colors. Depending on the topic of glass and color, let's get some "color" to see.

What is color?

Color is the visual effect of the human eye on light. The output of this visual effect depends on three aspects: ① the wavelength of light. ② the strength of light; ③ light color mixing ratio of white light. That is, hue (or hue), lightness (brightness), saturation (purity).

The light we see with the naked eye is generated by electromagnetic waves with a narrow wavelength range. Electromagnetic waves of different wavelengths appear in different colors. This is called "hue." We often say that the color red orange yellow green blue purple is the color.

The strength of the light entering the eye is "lightness", is a measure of the effect of light intensity on the visual. The color we talk about a thing often defaults to the color of the normal light in natural light. In the dark room, there is no color or darkness in everything because there is no light. Under the street light, the color of the leaves shows the dark green that we see during the day and the darkness of the light in the distance The color of leaves is black; this is the effect of light intensity on visual effects.

Saturation refers to the vivid color, also called color purity. Saturation depends on the mixing ratio of shades of light and white in the light. Containing more light color components, the greater the saturation, the more beautiful the color; the greater the white component, the smaller the saturation, the lighter the color.

What color are there in the glass?

Glass as a transparent material, in fact, an ordinary glass has two colors, through the color and reflection color; ordinary glass regardless of the front and back sides, both sides of the reflective color is the same; and coated glass on both sides of the reflective color is different , Often referred to as outdoor reflective or indoor reflective color (front reflective color and back reflective color).

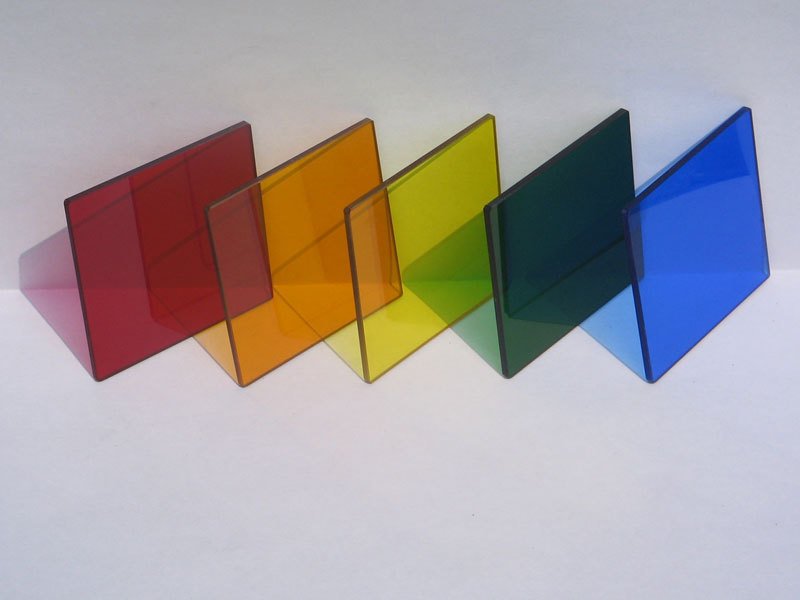

Through the color that natural light through the glass after the color. This color is actually the color we see through the glass and the color we see the glass on the white paper. The color of ordinary float glass is slight green. Some colored glass such as F green, blue, brown, etc. we often come into contact with, these are added to the raw materials in the glass production coloring ions, these colored ions produce a color.

The color of the reflection is the color of the glass that we see. In fact, we usually say that the color of building glass refers to the reflection color of glass. Most of our everyday objects are opaque, but all are reflective of these objects, so all we see is the reflective color of the object. The reflective color of glass is the color that the glass is placed in front of a black box.

Coated Glass Usually what we see outdoors is the outside reflective color of the glass; when we look out the window indoors, in fact we see everything outside the window with the glass's translucent color; at night when outdoors The light is dark, let's look at the glass on the curtain wall, in fact what we see is the internal reflection color of the glass.

Which colors are commonly used on glass?

There are several ways to produce color commonly used in glass: ① tinted glass, or more specifically called ontology tinted glass. ② glaze printing on glass or other ink to produce color. ③ give the glass color by coating. ④ By combining other colored materials, such as PVB, foil and other colors.

What are the characteristics of colored glass?

Common body coloring glass mainly F Green, European gray, crystal gray, light blue, dark blue, brown and so on. The color of the body coloring glass deepens as the thickness of the glass increases, that is, the deeper the color of the colored glass of the same color is, the heavier the color is. Ontological glass is added to the glass substrate pigment, pigment affects more than just the reflective color of glass, while the colored glass also through the color of the glass coloring. We often say that colored glasses, refers to the colored glass to see through it the physical color distortion.

The colored ions in the tinted glass actually have an effect on the infrared in the sunlight in addition to the visible light. In simple terms, F green colored glass is actually relative to ordinary white glass, the infrared filter has a certain degree of its infrared heat blocking effect with ordinary single silver LOW-E close. Therefore, F Green Glass is also used as heat-absorbing glass or heat-insulating glass in many places. Crystal gray, light blue and dark blue in the visible light and infrared light resistance is not much difference, which reduces the visible light transmission, but also reduces the infrared transmission. Another special color glass is European gray, gray European glass is a strong barrier to visible light, but its infrared blocking or filtering effect, but not as strong as visible light.

Why colored glass engineering applications do not have more transparent glass? Instead, packaging glass bottles often use colored glass?

Affect the application of colored glass in the construction of several main factors: ① colored glass through the color of the coloring, resulting in both long working life in the room or through the glass to see the outside feeling is not natural, a long time easy Have visual fatigue. ② the amount of colored glass relative to ordinary white glass is much less, the total output of less than 10% of ordinary glass. Converting from producing white glass to colored glass or from one colored glass to another colored glass produces a large number of over-color products. These over-color products are often only sold at low prices, resulting in the cost of colored glass to be higher than ordinary white glass. ③ colored glass is often stage production, and different manufacturers of colored glass can not be completely interchangeable. This led to large-scale projects from the perspective of supply security, the choice of colored glass more cautious.

The use of colored glass bottles is mainly to consider through the glass coloring to reduce the impact of light and infrared on the contents of the bottle. Continuous production using a single production line, while the bottles on the color uniformity and consistency of the less demanding.

Silk screen glass and color glaze with the color of how the resulting? Color how to describe?

Silkscreen glass and frit glass are produced by printing inks on glass. Screen printing glass generally refers to the use of low temperature ink printing glass; Caiyong glass is generally used in high temperature inorganic ink. Whether high-temperature ink or low temperature ink, the ink itself is usually opaque.

Silkscreen glass and frit glass can be simply understood as a paint on glass. The color of the pigment basically determines the color of the finished glass. The easiest way to measure the color of silk-screen and glazed glass is to use PANTONE, commonly used in the printing and dyeing industry. Pantone color card is invented by the Americans is an internationally accepted standard color card, color card has a common color of the label, each "color number" represents a color. The color of glazed or silkscreen glass can actually be measured by comparing color swatches.

In addition to Pantone color cards, there is a Raul color card, basically the same as Pantone, but only invented by Germans. These two color cards are world-renowned color authority and cover color communication systems in the fields of printing, textiles, plastics, graphics and digital technology. They have become the internationally accepted standard language for the exchange of color information today.

How is the color of coated glass produced?

The color of the coated glass is the result of the combined action of the glass substrate and the film. The lower the reflectance of the coated glass, the greater the reflection color of the substrate on the overall coated glass. At present, the coated glass has three or more layers, and the color of the coated glass is the result of the cooperation of all the layers. The material properties of each layer and the interference color of the layer thickness together form the color of the layer.

When we look at the color of the curtain wall glass, what we actually see is the color of the glass reflection. The results we observe are greatly influenced by environmental factors. The same piece of coated glass is observed under different light conditions. The difference is huge.

Conventional coated glass color what?

Not consider the use of colored substrates, the conventional coated glass colors are mainly colorless (natural color), blue-gray color, gold series. Colorless series of films tend to be very light color, showing the true qualities of the glass, commonly used in high lighting or permeability requirements of the relatively high building; conventional coated glass products are more blue-gray series, this series of films actually Film material and structure is not very different, but the difference between the level of reflectivity and color blue or gray partial difference. Golden coating, relatively speaking, now used less, but for some time because of its unique drip pride atmosphere all the rage.

Coated glass color how to describe?

The color of coated glass is commonly used in the glass industry as CIELab. CIELab is a color measurement space. It was built on the international standard of color measurement developed by the International Commission on Illumination (CIE) in 1931. In 1976, the revised was officially named CIELab. It is a device-independent color system and a color-based physiology system. This also means that it is a digitally-based way of describing human visual perception, a quantifiable measure of color description.

The L * component in the Lab color space is used to represent the brightness of the pixel, in the range of [0,100], from pure black to white; the closer to the L * the darker the color is (darker) L * Bright (light); In fact, the brightness of the glass material is proportional to the reflectivity, the higher the reflectivity, the greater the value of L *. a * indicates partial red (not enough red); b * indicates a yellowish-to-blue In the range of [127, -128]; + b * yellowish (not blue enough) -b * = blueish (not yellow enough).

Using CIELab color measurement, it is easy to figure out the difference between the two sample color is the color difference. In CIELab system with △ E * that color. 5CIELab . According to the provisions of the national standard coated glass, coated glass toward the outdoor surface in the use of the surface reflection color △ E * should not be greater than 2. 5CIELab color units.

From the color point of view how to choose coated glass?

Reflectance (brightness, L *) is the most important factor affecting the appearance of the glass. The high outdoor reflectance will make the glass look brighter and the low outdoor reflectance will make the overall dark look of the glass; however, the high outdoor reflectance will cause the glass to have a strong mirror effect in sunlight, which is also a problem of light pollution . High indoor reflectivity during the day has little effect, but in the case of the lights turned on at night will have a strong mirror effect.

Through the color closer to the neutral colorless the better, if you can not do a neutral colorless, light blue or light green is relatively easy to accept through the color. However, if the color is reddish or yellowish, it will be very bad for us to use it.

. Structural Glass Curtain Walls

. What is color! Simple Talking ...

. Advantages and uses of toughen...

. Various glass defects and solu...

Office Addr:Room 1107, B1 Block, Tianan Cyber,Nancheng Area, Dongguan City, Guangdong Province, China,

Factory Addr:Taiying Industrial, Hongmei Town, Dongguan City, Guangdong Province, China

86-769-22273585

86-18145870793

![]()