View: Time: 2017-11-6 21:56:32

How Tempered Glass?

Glass Tempered methon have two ways. Physical tempering and Chemical tempering.

I. Physical Tempering

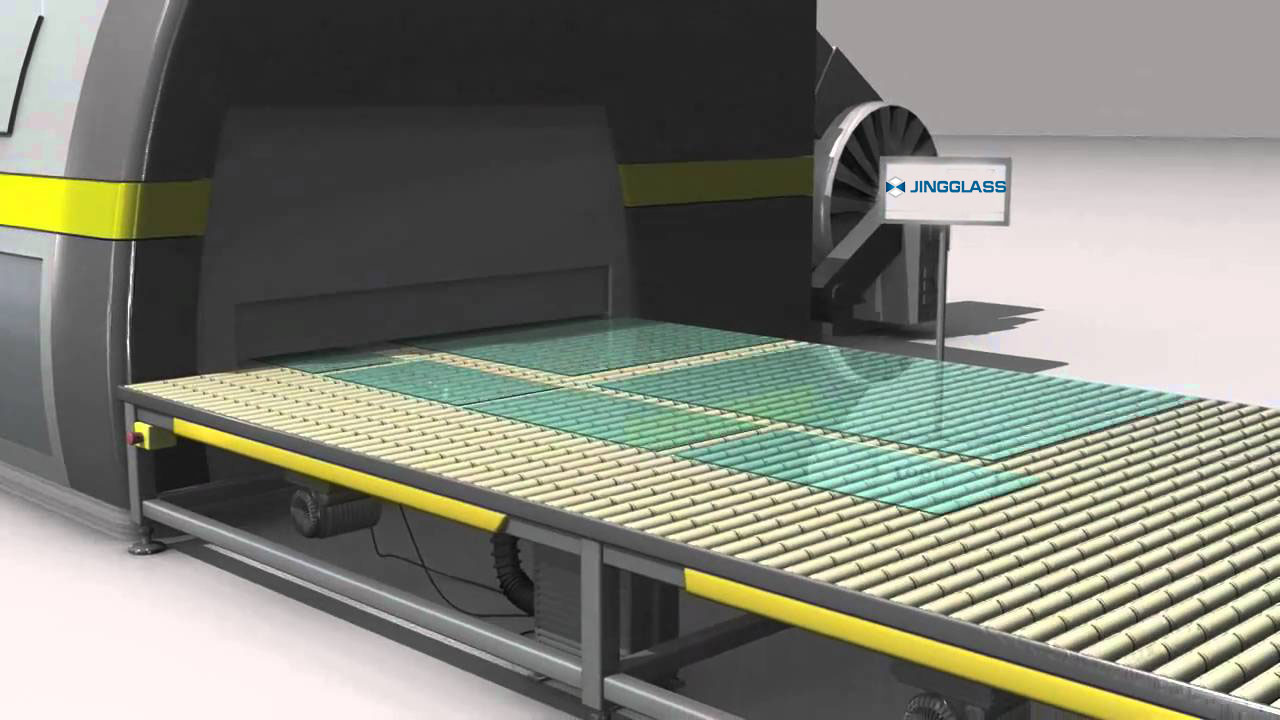

Physical tempering method is to heat the glass to near the glass softening temperature, and then both sides of the air blown at the same time to rapidly cooling to increase the glass mechanical strength and thermal stability of the production method. The quenching of heated glass is an important step in the production of toughened glass by physical toughening. The basic requirement for glass quenching is rapid and uniform cooling, so as to obtain uniform distribution of stress. In order to obtain a uniform cooling glass, cooling must be required The device effectively disperses the hot air to facilitate the removal of accidental broken glass and should be done

Reduce its noise.

Temperature of Float Glass Physical Tempering

Float Glass Tempered temperature normal is 650 to 720 °C. the heat keep time as the different. Eg. 3mm thickness float glass tempered heat time is about 30 s, 4mm thickness 40 s, 5mm thickness, heat keep time 50 s, and so on.

Methon of Glass Physical tempered

1. Gas medium tempered method

Gas medium steel method, that is air-cooled steel method.

Including the level of air cushion steel, horizontal roller steel, vertical steel and other methods. The so-called air-cooled steel method is to heat the glass close to the softening temperature of the glass (650 ~ 700.c), and then both sides of the air blown at the same time to rapidly cool to increase the mechanical strength and thermal stability of the glass production methods . The quenching of heated glass is an important step in the production of tempered glass by the physical tempering method. The basic requirement for glass quenching is rapid and uniform cooling, so as to obtain uniform distribution of stress. In order to obtain a uniform cooling glass, cooling must be required The device effectively evacuates the hot air, facilitating the removal of accidental broken glass and minimizing its noise.

Advantages and disadvantages:

Air-cooled steel has the advantage of lower cost, large output, high mechanical strength, thermal shock resistance (maximum safe working temperature up to 287.78.c) and high heat gradient Subject to 204.44.c), and air-cooled tempered glass in addition to enhancing the mechanical strength, the formation of small fragments in the crushing, can reduce the harm to the human body.

However, the thickness and shape of the glass have certain requirements (the minimum thickness of toughened glass made in domestic equipment is generally above 3mm), and the cooling speed is slow, the energy consumption is high and the power consumption is large. For the thin glass, the tempering process still exists Glass deformation problems, can not be applied in the field of high optical quality requirements.

Scope of application:

At present, the air toughening technology is widely used. Air toughened glass is mostly used in automobiles, ships and buildings.

2. Liquid Medium Tempering

liquid medium tempering method, that is a liquid-cooled method.

Liquid cooling method is to heat the glass to near softening point, release filled with liquid quench tank for tempering. In this case, brine can be used as the cooling medium, for example, mixed brine such as potassium nitrate, potassium nitrite, sodium nitrate and sodium nitrite. In addition, you can also use mineral oil as a cooling medium, of course, mineral oil can also add toluene or carbon tetrachloride and other additives. Some special quenching oil and silicone oil can also be used. In the liquid steel, because the edge of the glass into the quench tank first, so there will be uneven stress caused by the burst. In order to solve this problem, it can be pre-cooled with air-cooled or liquid-jet first, and then placed in organic liquid Chilled. You can also put in the quench tank water and organic solution, the organic solution floating on the water, when the heated glass into the tank, the organic solution to play a pre-cooling effect, absorb some of the heat, and then quickly cooled into water In addition to Using immersion cooling liquid, liquid spray method can also be used, but the general use of immersion method. British triplex company, the earliest in the 1980s on the liquid medium method of steel thickness of 0.75 ~ 1.5mm glass, the end of the physical tempering can not tempered thin glass history. The difficulty of liquid steel method is to establish a reasonable liquid-cooling process system, liquid cooling steel should pay attention to two issues: First, the resulting high compressive stress layer, the second is to avoid glass burst.

Advantages and disadvantages:

The liquid medium tempering method, due to the larger water specific heat, gasification heat is high, so significantly reduce the amount, thus reducing energy consumption, reduce costs, and cooling speed, high safety performance, deformation is small.

As the glass is cooled and inserted into the liquid medium after it is heated, it is easy to heat unevenly and influence the quality and yield for the glass panels with larger area.

Scope of application:

Mainly suitable for tempering a variety of thin glass, such as glasses. LCD glass, glass and other optical instruments.

3.Particle tempering method

After the glass is heated to near the softening temperature, the solid particles in the fluidized bed are generally obtained by quenching the alumina particles with a particle size of less than 200m to enhance the glass. In theory, solid as a cooling medium can be made of thinner, lighter, higher strength tempered glass, so the mid-70s of last century to the early 80s, the United Kingdom, Japan, Belgium, Germany, one after another to apply this technology In the production.

Advantages and disadvantages:

Particle tempering method can be ultra-thin glass. High strength, good quality. Is currently manufacturing high-performance glass of an advanced technology. Particle tempering of new technology compared with the traditional wind-tempering process. Cooling medium cooling capacity for steel ultra-thin glass, energy-saving effect (saving about 40%).

However, the particle tempering process of the cooling medium cost is higher.

Scope of application:

High-strength, high-precision thin glass and ultra-thin glass.

4.Fog tempering method

The use of atomized water as a cooling medium, the use of spray exhaust equipment, the glass can be tempered in the process of cooling more uniform, smaller energy consumption, better performance after tempering. Spray exhaust equipment by a number of parallel with each other and arranged on the bottom of the grid-shaped barrel structure, each barrel structure by the floor, partitions, nozzles and a number of exhaust larvae l composition. Similar to the gas method, the cooling medium used is not air but atomized water. Characterized by atomized water as a cooling medium, the glass is tempered. The specific heat of water is larger, and the water vaporization heat of all liquids is also the highest. During the tempering process of the glass, the water mist is continuously sprayed onto the surface of the heated glass. The atomized water in the form of particles absorbs heat quickly to become 100 ° C. water, and then is gasified. The water has a large specific heat and a heat of vaporization High this feature. A large amount of heat on the glass surface instantly taken away (absorption), the glass quenching and tempering, in the glass surface caused by permanent compressive stress, thereby enhancing the tensile strength of glass, the glass tempering. Water mist (atomized water) can be sprayed by compressed air injection method, steam injection method or hydraulic spray method to the heated glass surface, because the atomized water comes into contact with the red glass will quickly absorb heat and gas expansion , If it is free to spread. It will affect the uniform cooling glass, easy to make glass burst. to this end. Need to design a unique spray exhaust equipment, making the gasification and expansion of water vapor can be pumped away. Without spreading along the glass surface.

Advantages and disadvantages of fogging:

cooling medium is easy to get, low cost, does not pollute the environment, but also tempered the general gas, liquid and particle steel can not be toughened thin glass. However, the cooling uniformity is more difficult to control.

Scope:

Because of its cooling system more difficult to control, the current application less.

II. Chemical Tempering.

Chemical tempering method that is through chemical methods to change the glass surface components, increase the surface lamination stress, in order to increase the mechanical strength and thermal stability of glass. Because it is through ion exchange to enhance the glass, it is also known as ion exchange enhancement. According to the type of ion exchange and ion exchange temperature can be divided into below the transition point temperature ion exchange method referred to as low temperature method and higher than the transition point temperature

The ion exchange method referred to as high temperature method.

Advantages and Disadvantages:

The strength of the chemically strengthened glass is close to that of the physical enhanced glass, the thermal stability is good, the light transmittance is good, the surface strength is high, the processing temperature is low, the product is not deformed, and the product is not limited by the thickness and the geometric shape. The product is easy to implement. However, compared with physical tempered glass, chemically tempered glass production cycle is longer, debris and ordinary glass similar. Scope: Chemical tempered glass is widely used in different thickness of flat glass, thin-walled glass and jar shaped glass products, can also be used for fire-resistant glass.

Now for Safety and Environmental protection, most tempered Glass by Physical Tempering.

Contact US:

Email: op@jingglass.com;

Info@jingglass.com;

Whatsapp: 0086-18145870793

. Structural Glass Curtain Walls

. What is color! Simple Talking ...

. Advantages and uses of toughen...

. Various glass defects and solu...

Office Addr:Room 1107, B1 Block, Tianan Cyber,Nancheng Area, Dongguan City, Guangdong Province, China,

Factory Addr:Taiying Industrial, Hongmei Town, Dongguan City, Guangdong Province, China

86-769-22273585

86-18145870793

![]()