View: Time: 2017-12-18 23:58:04

Laminated glass is paid more and more attention because of its safety and high. In the field of architectural glass EVA, PVB, SGP, zhengqidouyan, today we have to talk about these types of laminated film.

EVA and Tempered EVA Laminated Glass

The full name of EVA is ethylene vinyl acetate copolymer. Water resistance, corrosion resistance, is widely used in foaming shoes material, functional films, packaging film, hot melt adhesive (term "hot melt" provided by the industry Encyclopedia), wire and cable and toys and other fields in our country, EVA is mainly used to do sole material.

As the EVA film used as sandwich glass, compared with PVB or SGP, the melting temperature of EVA is lower and the fluidity is good at about 110 C. The simple vacuum and heating can meet the production needs of EVA laminated glass, and only about 100 thousand of the production equipment is needed.

The EVA film has good fluidity, suitable for wired, entrainment and other operations in the film, making patterns, rich decorative glass material. EVA has good water resistance, but it is resistant to UV and is easy to yellowing and aging in sunlight. At present, EVA laminated glass is mainly used for indoor partition and more decoration, and outdoor curtain wall is generally not suitable for using EVA.

Solar panel panel (word "panel" is provided by industry Encyclopedia) domestic use of more EVA, but now there is a trend to use PVB to replace EVA.

PVB and Tempered PVB Laminated Glass

PVB, polyvinyl butyral, with high transparency, cold resistance, impact resistance, resistance to ultraviolet radiation. PVB is the most widely used laminated material for building glass and automobile glass at present.

Compared with EVA, the storage and processing technology of PVB interlayer is much more complicated. General requirements PVB between when the temperature is 18-23 DEG C, relative humidity 18-23%, PVB moisture (entries "water content" provided by industry Encyclopedia) 0.4%-0.6%, after preheating rolling ("rolling" entries provided by industry Encyclopedia) or vacuum, also need to use an autoclave at 120-130 DEG C, 1.0-1.3MPa insulation the pressure for 30-60 minutes. PVB laminated glass production equipment needs about 1 million.

PVB laminated glass has the advantages of safety, good sound insulation (term "noise" provided by the industry Encyclopedia) resistance and ultraviolet radiation, but PVB water resistance is poor, long-term soaking wet glue is easy to fall off. 7-8 years ago the PVB film with imported DuPont, Solutia, three water factories. In recent years, the development of domestic PVB has been developing rapidly, but most of the domestic manufacturers use recycled materials for two times processing, and the quality stability is relatively poor. The domestic PVB use is not enough from the raw material PVA.

SGP & Tempered SGP Laminated Glass

The full name of SGP is Sentry Glas Plus. It is a high-performance sandwich material developed by DuPont Co. Now its patent and production line has been sold to Japan Cola company.

SGP has high strength and shear modulus, and the mechanical properties ("mechanical properties" are provided by the industry Encyclopedia). The bearing capacity of SGP laminated glass is 2 times the carrying capacity of PVB with equal thickness. Meanwhile, under the condition of equal load and equal thickness, the flexural deflection of SGP laminated glass is only 1 / 4 of PVB sandwich glass.

The tear strength of SGP laminated film laminated film is 5 times of PVB, even in case of broken glass, SGP film can also bond broken glass to form a temporary structure after the destruction, the bending deformation ("bending" entries by industry encyclopedia provides) small, can bear a certain amount of load without the whole piece fall.

The SGP film has good edge stability and is not sensitive to water. SGP laminated film is colorless and transparent, and good weather resistance, not easy to yellow. The yellowing coefficient of SGP film is less than 1.5, while the yellowing coefficient of PVB film is 6~12, so the ultra white interlayer is more SGP.

SGP production process is close to PVB, and the equipment can be used to produce PVB equipment. The higher price is the reason for the slower acceptance of the SGP market. A (Eastman has been a chemical acquisition) and DG SGP Zhong in the film close to the low awareness.

. Structural Glass Curtain Walls

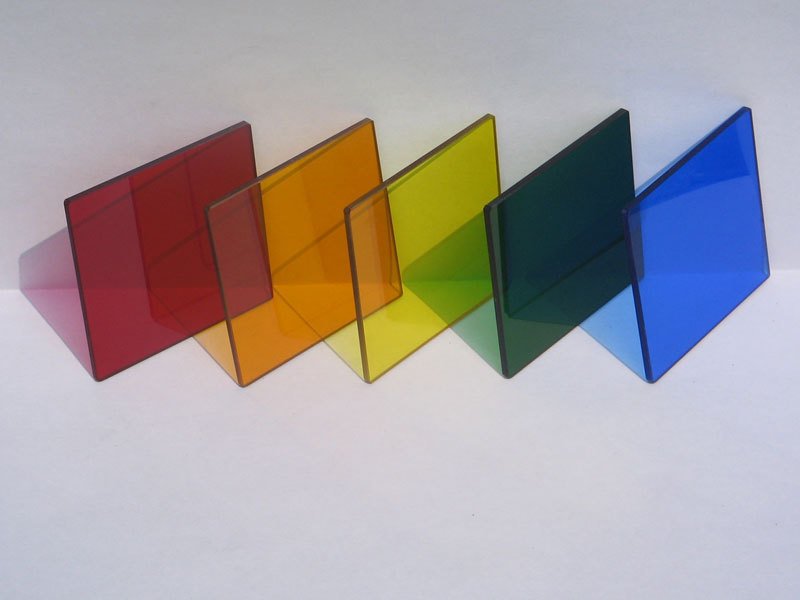

. What is color! Simple Talking ...

. Advantages and uses of toughen...

. Various glass defects and solu...

Office Addr:Room 1107, B1 Block, Tianan Cyber,Nancheng Area, Dongguan City, Guangdong Province, China,

Factory Addr:Taiying Industrial, Hongmei Town, Dongguan City, Guangdong Province, China

86-769-22273585

86-18145870793

![]()